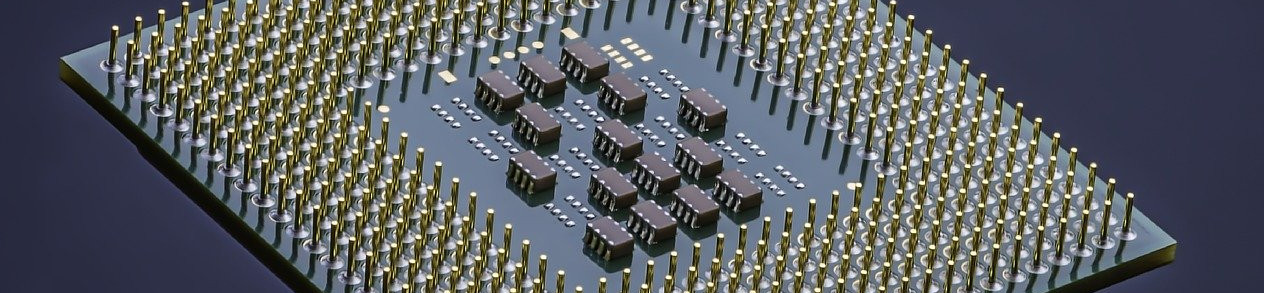

Microsystem Fabrication & Test

About the course

The students know the structure and functionality of Tools for the layout design of integrated systems. You understand the underlying principles of these tools algorithms and are able to apply this knowledge when using the tools for concrete design tasks. The students are able to solve a complex design task to understand, to analyze in a team and to develop a design project organize. You are able to create an integrated system using professional design software in a team and to design for to prepare the production by a semiconductor manufacturer. The students can carry out a simple development project in Organize and execute the team independently. The testing lecture is divided into two parts. The first part of the lecture deals with the rotating storage media, so on the one hand the different types polycarbonate media (CD, DVD, BluRay), on the other hand the hard disks. The underlying technology is presented and the limits that are currently foreseeable. The second part deals with semiconductor memory. Classical cells are SRAM and DRAM as well as EEPROM for the non-volatile memory. There is a whole series of technologies based on different physical principles. On the basis of the cells then developed the architecture of a memory with its hierarchy of sense amplifiers. The final part is the interfaces, which are responsible for the actually achievable performance of are of extreme importance.

Curriculum

Fabrication

1. examples, fields of application, markets, technology forecasts

2. silicon-based microtechnology:

a. lithographic structure transfer (photolithography,

b. electron beam lithography, X-ray lithography)

c. etching process (crystallogrphic etching process,

d. dry etching process, etching simulation)

e. coating processes (PCD, CVD)

f. clean room technology

3. classic manufacturing processes in microtechnology:

a. spark erosion,

b. machining production processes,

c. laser-based microtechnology,

d. plastic impression techniques,

e. electroforming

4. special microstructuring processes:

a. LIGA technology,

b. microstructuring of glass

5. nanotechnology:

a. basics

b. top-down techniques

c. bottom-up techniques

d. perspectives

6. Microsystems Technology at the Chair of Microsystems Design:

a. design methodology

b. process design

Test:

1. the students know the memory pyramid of registers,cache, main memory and mass storage up to archive systems,

2. have an overview of the different methods for storage on rotating media, whereby the

3. view into the future is essential,

4. have understood where the limits of the spear density on hard disks, are able to store volatile and non-volatile memory explain and explain the technologies and

5. have learned to distinguish well between the ideally possible and in the values occurring in practice, e.g. in the case of interfaces.

Credit hours

Presence Lecture 30 h; Follow-up and self-study 20 h, Internship - briefing and preparation 15 h, internship - Design execution 70 h; exam preparation 15 h.Your Instructor.

Dr. Michael Wahl

Raum: H-C 6326

Tel.: 0271 740 2474

E-Mail: michael.wahl@uni-siegen.de